Packaging Printing Process - Edge Brushing Process

The packaging edge brushing process is the process of cutting the edges of paper packaging such as packaging boxes, notebooks, picture books, etc., and applying ink and paint manually or mechanically to achieve edge coloring or texture decoration. The core function is to cover the cutting edges, enhance visual layers, and make the packaging more high-end and exquisite.

Core Process Principles

Preprocessing: Polish the edges of the cut packaging to remove burrs and edges, ensuring a smooth surface.

Coloring coating: By hand brushing, machine rolling, or spraying, the specialized ink/paint is evenly applied to the edges.

Curing and drying: Natural air drying or low-temperature drying (40-60 ℃) to ensure the coating adheres firmly and avoid color fading and contamination.

Refined processing: Some high-end crafts will polish the edges twice to ensure uniform color and smooth touch.

Core process types and applications

1. Solid color edge brushing

Features: Apply a single color (black, red, gold, silver, etc.) evenly, with full color and simple operation.

Application scenarios: notebook cover, cultural and creative gift box, book binding.

2. Gradient brush edge

Features: Two or more colors naturally transition and require precise manual control, resulting in a dynamic visual effect.

Application scenarios: high-end cosmetics gift boxes, trendy toy packaging, personalized customized boxes.

3. Metallic brushed edges

Features: Using metallic pigment ink, presenting a metallic luster such as cash, silver, copper, etc., enhancing the sense of luxury.

Application scenarios: tobacco and alcohol gift boxes, luxury goods packaging, high-end gift boxes.

4. Texture brushed edges

Features: Adding fillers such as matte powder and fine glitter powder to create a matte, pearl or glitter texture, with a dual upgrade of touch and visual appeal.

Application scenarios: beauty gift boxes, cultural and creative product packaging, children's toy boxes.

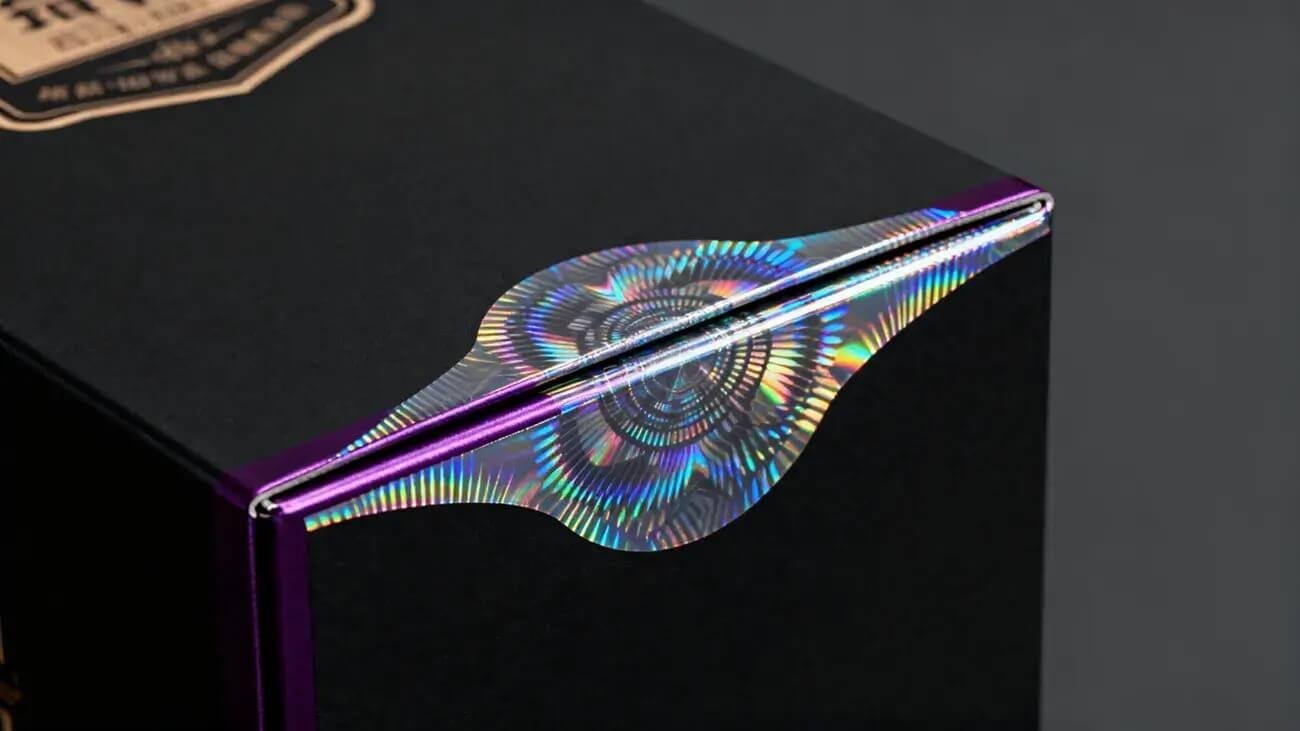

5. Alien brush edge

Features: Precise brushing and coating for irregular cutting edges (such as circular and wavy shapes), suitable for special shaped packaging.

Application scenarios: Alien food boxes, holiday gift packaging, customized gift boxes.

Key elements: materials and tools

1. Common Coatings and Characteristics

Specialized brush edge ink: Strong adhesion, not easy to fade, available in matte, glossy, metallic and other types, suitable for paper substrates.

Acrylic pigment: Rich in color, fast drying, suitable for handmade customization, but needs to be paired with a fixing agent to enhance durability.

UV coating: requires UV light curing, fast drying speed, wear-resistant and scratch resistant, suitable for large-scale machine production.

Special fillers: frosted powder, glitter powder, gold powder, etc., used to create a textured brushing effect.

2. Core tools and equipment

Hand tools: brush, sponge brush, scraper, suitable for small batch, personalized orders, high flexibility.

Semi automatic equipment: Roll coating machine, spray machine, suitable for medium batch production, with better coating uniformity than manual.

Fully automatic production line: including integrated equipment for polishing, coating, curing, and finishing, suitable for large-scale orders, with high efficiency and precision.

Core advantages and applicable scenarios

Advantage

Highly decorative: By enhancing the color and texture of the packaging edges, ordinary packaging appears more exquisite.

Concealing flaws: Covering the burrs and white edges after cutting, optimizing the overall appearance of the packaging.

Cost controllable: Manual craftsmanship does not require complex equipment, and small batch customization has low costs; Machine production is suitable for large quantities and has high efficiency.

Flexible adaptation: can be combined with hot stamping, UV polishing and other processes to achieve diverse decorative effects.

Applicable scenarios

Cultural and creative products: laptops, hand books, picture books, postcards, etc.

High end gift boxes: cosmetics box, gift box, tobacco and alcohol box, luxury goods packaging.

Personalized packaging: customized gift boxes, trendy toy packaging, holiday limited edition packaging.

Common faults and solutions

Uneven color: The reason is due to improper dilution ratio of the coating and inconsistent application force. The solution is to standardize the dilution ratio of the coating, maintain a constant speed of application during manual operation, and calibrate the rolling pressure during machine production.

Edge ink overflow: The reason is due to excessive coating and uncontrolled application range. The solution is to reduce the amount of single coating by using masking paper to cover the non brushed edge area and accurately control the application range.

Coating detachment: The reason is that the substrate has not been pre treated and the coating selection is improper. The solution is to polish the edges to remove oil stains, use specialized brush ink suitable for paper, and apply primer if necessary.

Slow drying: The reason is high environmental humidity and high moisture content in the coating. The solution is to improve environmental ventilation by using fast drying coatings or using low-temperature drying assisted curing.