Packaging Printing Processes – Die Cutting and Creasing

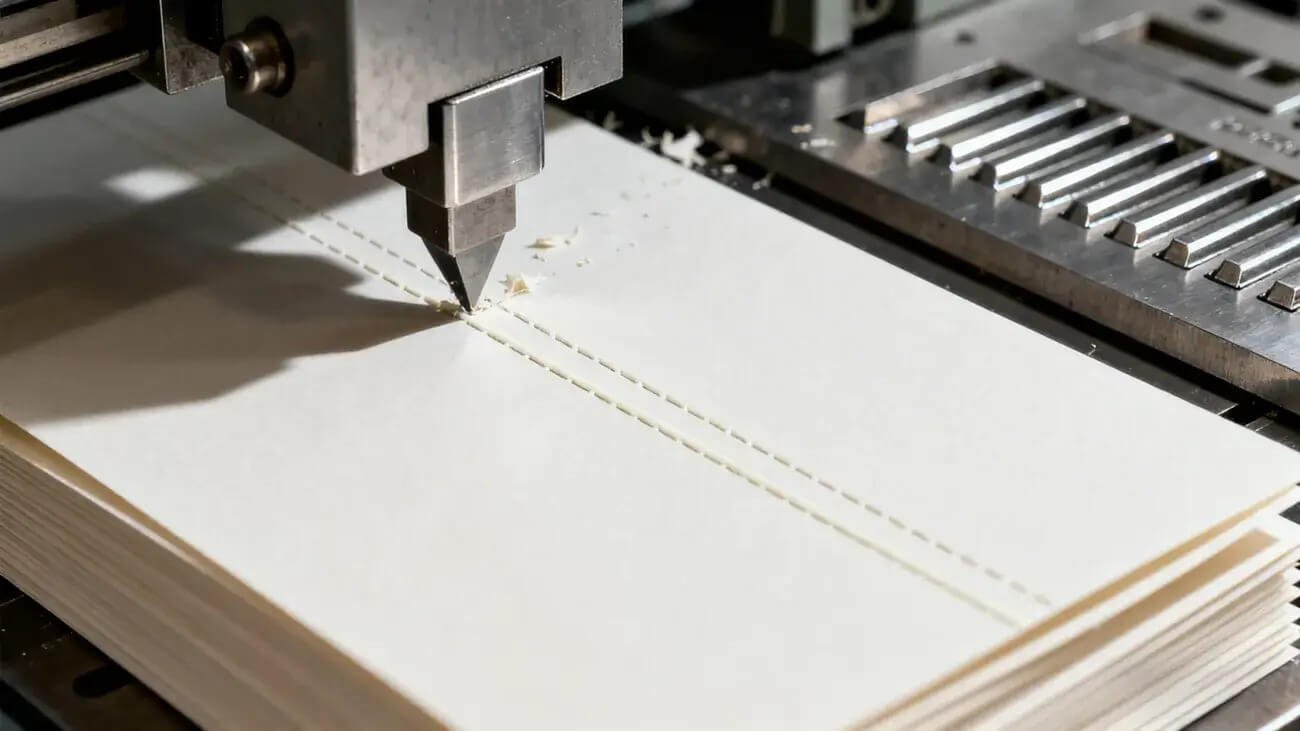

Packaging die-cutting and indentation are key processes in post printing processing of packaging, and they are often used in conjunction - die-cutting is responsible for cutting the packaging blank into the target shape, while indentation is responsible for pressing precise creases, jointly ensuring the forming accuracy and user experience of the packaging.

Core Process Principles

Die cutting process: By applying pressure through a die-cutting plate (a steel knife engraved with a target shape), paper, cardboard and other substrates are cut and separated to form irregular or customized contours.

Indentation process: By using the combination of indentation lines and indentation bottom molds, concave creases are pressed on the substrate to ensure precise alignment and prevent breakage during packaging folding.

In actual production, the "die-cutting+indentation integrated version" is often used to complete cutting and indentation in one go, improving efficiency.

Core components

Die cutting version: The mainstream is steel knife die cutting version, and the knife height and thickness are adjusted according to the thickness of the substrate (such as 2mm cardboard suitable for 23.8mm high steel knife). Fine patterns require high-precision engraving.

Indentation component: The indentation line (metal strip) is matched with the indentation base mold (elastic material), and the indentation depth needs to match the weight of the substrate (the higher the weight, the deeper the indentation).

Die cutting equipment: flatbed die-cutting machine (suitable for high precision, small batch), circular die cutting machine (suitable for high-speed, large batch production), pressure control accuracy needs to reach ± 0.1kg/cm ².

Core strengths

Accurate molding, die-cutting tolerance can be controlled within ± 0.1mm, straight indentation creases, ensuring packaging splicing and folding effects.

Wide adaptability, can handle various substrates such as paper, cardboard, plastic, leather, etc., to meet different packaging needs.

High efficiency, the integrated process can achieve 500-2000 processing times per minute, suitable for large-scale production.

Common types and application scenarios

1. Flatbed die-cutting and indentation

Technical features: uniform pressure, high precision, suitable for complex shapes and fine graphics and text.

Application scenarios: gift boxes, cosmetics boxes, and packaging for irregular food items

2. Circular die cutting and indentation

Technical features: High speed continuous processing, low loss, suitable for long form orders.

Application scenarios: Express cardboard boxes, beverage packaging boxes, daily necessities packaging

3. Digital die-cutting indentation

Technical features: No need to make physical die-cutting plates, suitable for small batch and personalized orders

Application scenarios: Packaging of cultural and creative products, customized gift boxes

4. Holographic die-cutting indentation

Technical features: Combining holographic hot stamping and die-cutting indentation, it has both decorative and molding functions.

Application scenarios: high-end health products, electronic product packaging

Common faults and solutions

Uneven die-cutting/burrs: The reason is that the steel knife becomes dull and the pressure is insufficient. The solution is to replace the steel knife with a new one and increase the pressure by 0.2-0.5kg/cm ² according to the thickness of the substrate.

Unclear indentation/folding fracture: The reason is insufficient indentation depth and high moisture content of the substrate. The solution is to deepen the indentation depth and control the moisture content of the substrate at 8% -12%.

Offset of die-cutting position: The reason is inaccurate positioning of the substrate and loose die-cutting plate. The solution is to adjust the positioning device, re fix the die-cutting plate and calibrate it.