In the fast-paced retail industry, the efficiency of packaging is equally important as the quality of the product itself. For brands that pursue a balance between cost-effectiveness, structural integrity, and aesthetics, plug-in boxes are undoubtedly a versatile choice. Crown Win Manufacturer has 18 years of professional experience in the paper packaging industry, and we deeply understand how a suitable packaging box structure can optimize the supply chain and enhance brand image.

Core positioning of socket box

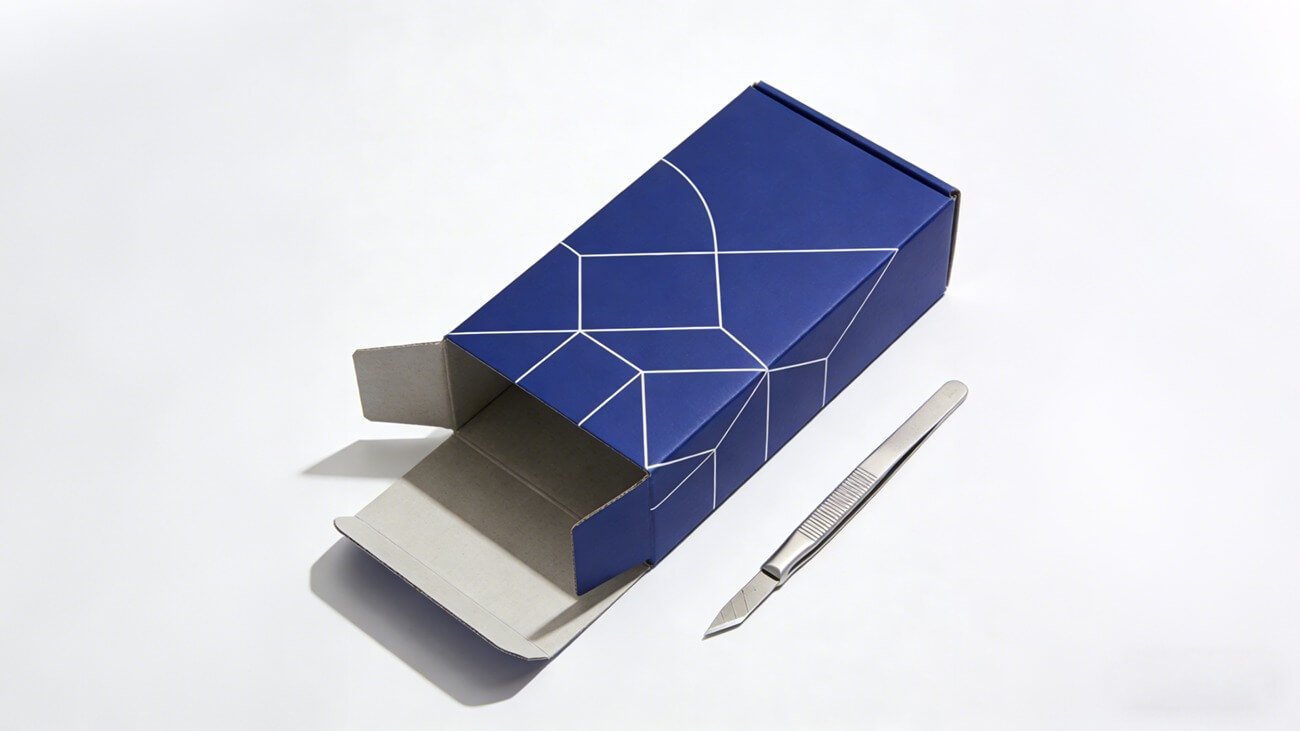

The characteristic of the socket box lies in its foldable socket, with two configurations of straight socket (STE) and reverse socket (RTE). This design can achieve firm closure, convenient assembly, and provide safe product protection. Its core value lies in balancing functionality and brand exposure, thus solving the two major pain points faced by enterprises:

1. Prevent product damage during transportation.

2. Provide consumers with a convenient opening experience.

For small and medium-sized brands or individuals launching new products, the simple design of foldable packaging boxes can reduce storage and transportation costs (as they can be packaged flat), and their customizable surface provides ample space for brand identification, product information, and creative design. In industries such as cosmetics and jewelry, aesthetics directly affect consumers' purchasing decisions. Carefully designed foldable packaging boxes can present a simple and professional visual effect, perfectly integrating into retail shelves.

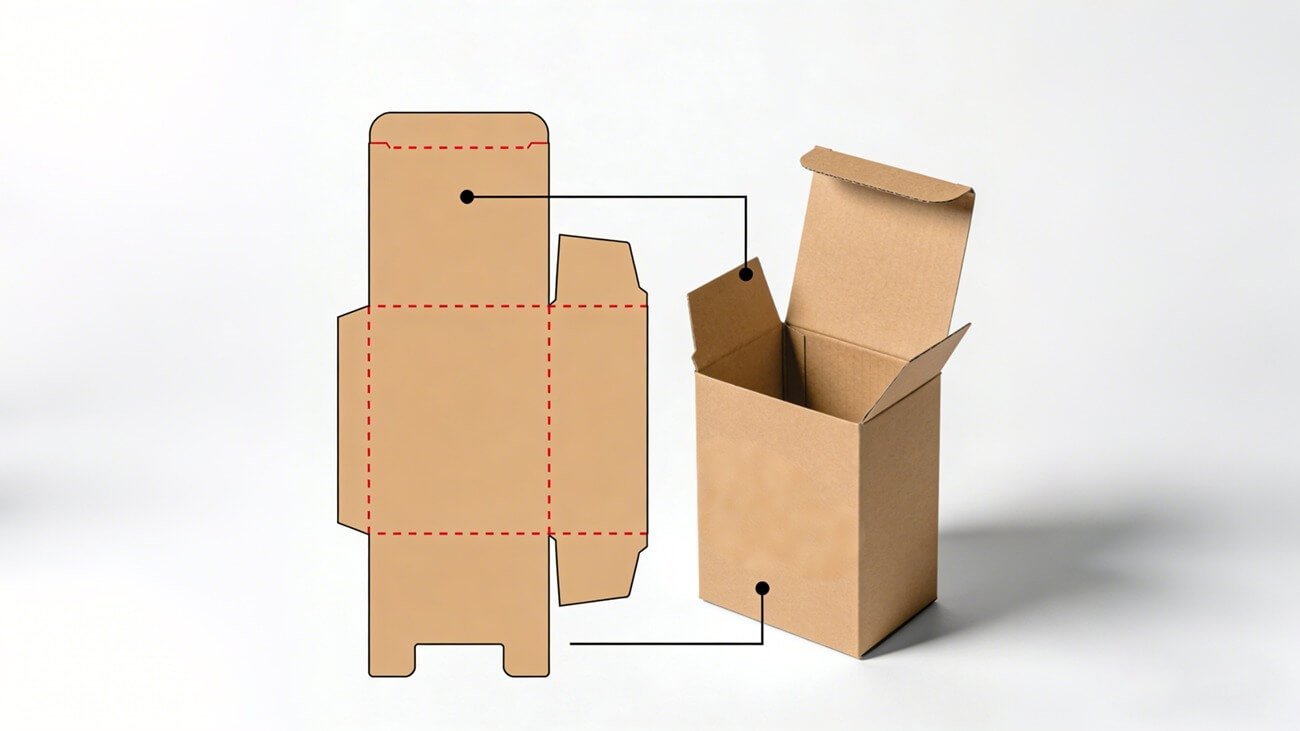

The core advantage of a plug-in box lies in its simplicity. In many cases, this type of cardboard box can be assembled without the need for glue, making it both environmentally friendly and labor-saving. For brands that want to reduce their carbon footprint while maintaining a high-end texture, this paper packaging is an ideal alternative to plastic packaging.

Why is Crown Win Manufacturer the preferred supplier for socket boxes?

For enterprises or individuals who need to customize foldable packaging boxes, choosing the right manufacturer is equally important as the design itself. Many brands face problems such as unstable quality, long delivery cycles, or limited customization options - and with 18 years of industry experience, we have successfully solved these problems. This means that we have a comprehensive service model, from the initial die line design to the final global logistics. When you purchase socket boxes from us, you will directly cooperate with a source factory that understands the subtle differences in paper weight, texture direction, and folding strength. Our mission is to provide packaging solutions for small and medium-sized brands around the world, ensuring that they can easily obtain high-end quality without facing various obstacles in complex international manufacturing processes. The sentence is:.

The main performance advantages of product packaging socket boxes

1. Easy to assemble and use: Designed specifically for fast manual or automatic filling, minimizing bottlenecks on the production line.

2. Space utilization: These boxes can be transported in flat packaging, significantly reducing storage and transportation costs.

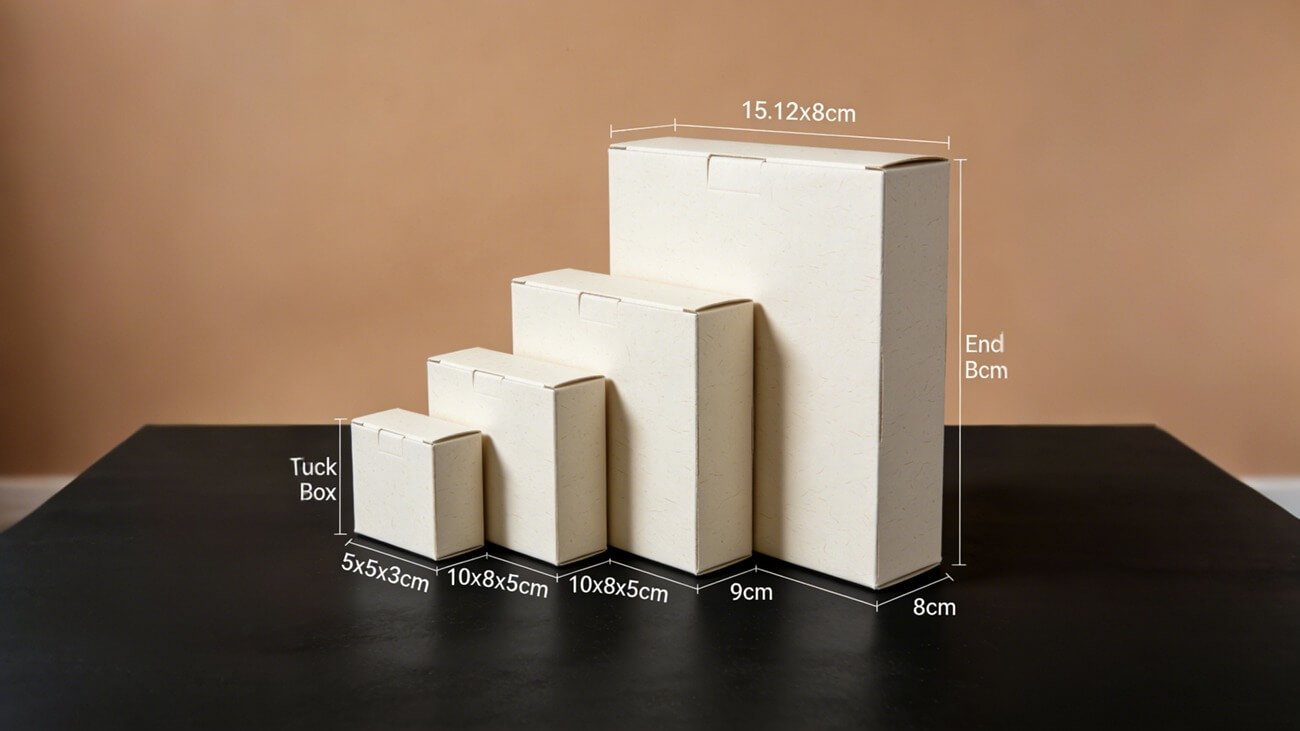

3. Diversified customization options: Whether you need simple and stylish packaging boxes or luxurious and exquisite packaging boxes, we can provide a wide range of customization options, including size, shape, paper materials (kraft paper, copperplate paper, specialty paper), printing processes (offset printing, digital printing, UV printing), and surface treatments (matte, glossy, partial UV, embossed).

4. Sustainability: As experts in paper packaging, we provide recyclable and biodegradable materials for product packaging boxes, helping brands achieve sustainable development goals and attracting environmentally conscious consumers - meeting the growing market demand.

Provide unlimited customization options for your product packaging

At Crown Win Manufacturer, we believe that your packaging should be as unique as your brand. We offer a wide range of printing and surface treatment processes for you to choose from, ensuring that your product packaging box is eye-catching enough:

Printing: We use CMYK four-color printing and Pantone color matching technology to ensure that your brand colors are bright and consistent in every batch.

Touch: Enhance the unboxing experience through embossing, intaglio printing, or soft touch film coating.

Hot stamping: Apply hot stamping or silver stamping technology and partial UV coating on the product packaging box to highlight your brand logo or key product characteristics.

Multiple material options: From eco-friendly kraft paper, high-density white cardboard to textured specialty paper, choose materials that align with your brand philosophy and sustainable development goals.

Practical considerations for choosing a tongue insertion box

When designing product packaging boxes, practical factors must be considered to avoid common defects. One of the major pain points faced by brands is "box bulging", where the cardboard bends and deforms under the weight of the product. Our engineers solve this problem by selecting the appropriate weight (GSM) and structural reinforcement measures, and customizing according to the weight of your product.

In addition, we ensure that the die-cutting process adopts high precision. Cutting rough socket boxes can cause the box cover to be misaligned, leaving a "cheap" impression on consumers. At Crown Win Manufacturer, our production line guarantees that every fold is clear and neat, and every seal is tightly sewn, maintaining the professional image that your brand should have.

Common questions about socket boxes

Q: What is a folding packaging box? What is the difference between direct insertion and reverse insertion socket boxes?

Answer: The two flip covers of the Straight Tuck End Box used for product packaging are folded to the same side, making the front appearance more concise and beautiful. The Reverse Tuck box saves space and is commonly used for packaging products such as toothpaste or cosmetic hoses.

Q: Can you provide samples of product packaging folding boxes before mass production?

Answer: Yes. As a customer-centric factory, we provide structural samples before mass production to ensure perfect size fit, followed by comprehensive printing and post-processing processes.

Q: Are your product packaging folding boxes environmentally friendly?

Answer: Of course. We are committed to environmental practices, using recyclable materials and eco-friendly inks to help your brand meet the growing demand for green and eco-friendly packaging from consumers.

Plug in paper box is a multifunctional, cost-effective, and brand enhancing solution suitable for enterprises in various industries. Investing in high-quality product packaging folding boxes produced by Crown Win Manufacturers, you can obtain customized plug in paper boxes to solve your packaging problems and enhance your brand image. Whether you need a small amount for new product launches or large-scale production for existing product lines, we can help you meet your packaging needs. Contact Crown Win Manufacturers now for free inquiry.