Most small and medium-sized brands face the challenge of how to choose custom paper packaging materials and processes: how to choose materials that balance durability and cost, how to match printing processes with brand aesthetics, and how to strike a balance between sustainable development goals and actual performance. Crown Win Manufacturer has 18 years of experience in custom paper packaging printing and is committed to simplifying material, process, and practical choices for customers, helping you get rid of blind exploration. This guide will provide you with practical insights to help you align packaging decisions with brand goals and avoid costly mistakes.

Core positioning: A solution centered on materials and processes

We focus on simplifying complex paper packaging materials and processes for small and medium-sized brands around the world. Unlike general suppliers who offer generic solutions, we tailor recommendations based on the unique needs of your product - whether you need FSC certified paper to enhance environmental awareness, high-precision printing to showcase fine brand details, or sturdy structures to ensure product transportation safety. Our core goal is to transform our technical expertise into solutions that are easy for customers to understand and cost-effective, truly serving your business.

Why are we the best choice to meet your material and process needs

Most brands face three major pain points in packaging materials and processes - and we solve them one by one with data-driven precision solutions:

1. Too many material choices: We will analyze in detail the advantages, disadvantages, and application scenarios of FSC certified paper, recycled paper, and corrugated cardboard to help you avoid paying too high a price for high-quality materials or choosing inferior materials that may cause product damage and returns.

2. Printing process mismatch: Many brands waste budget on the wrong process - for example, using screen printing to print fine text, resulting in blurry logos. We will match the appropriate craftsmanship for you based on your design requirements, budget, and brand aesthetics.

3. Balance between sustainability and durability: Environmentally friendly materials often lack strength - we use FSC certified paper combined with water-based ink to ensure structural integrity while also meeting environmental commitments, thus solving this problem.

Key advantages in materials and processes

Our technological strength surpasses many basic packaging solutions on the market:

-Material diversity: We purchase FSC certified paper (120-400gsm), recycled corrugated cardboard, and specialty paper, and can customize thickness according to product requirements, from lightweight cosmetics to heavy-duty electronic products, to meet the needs of different products.

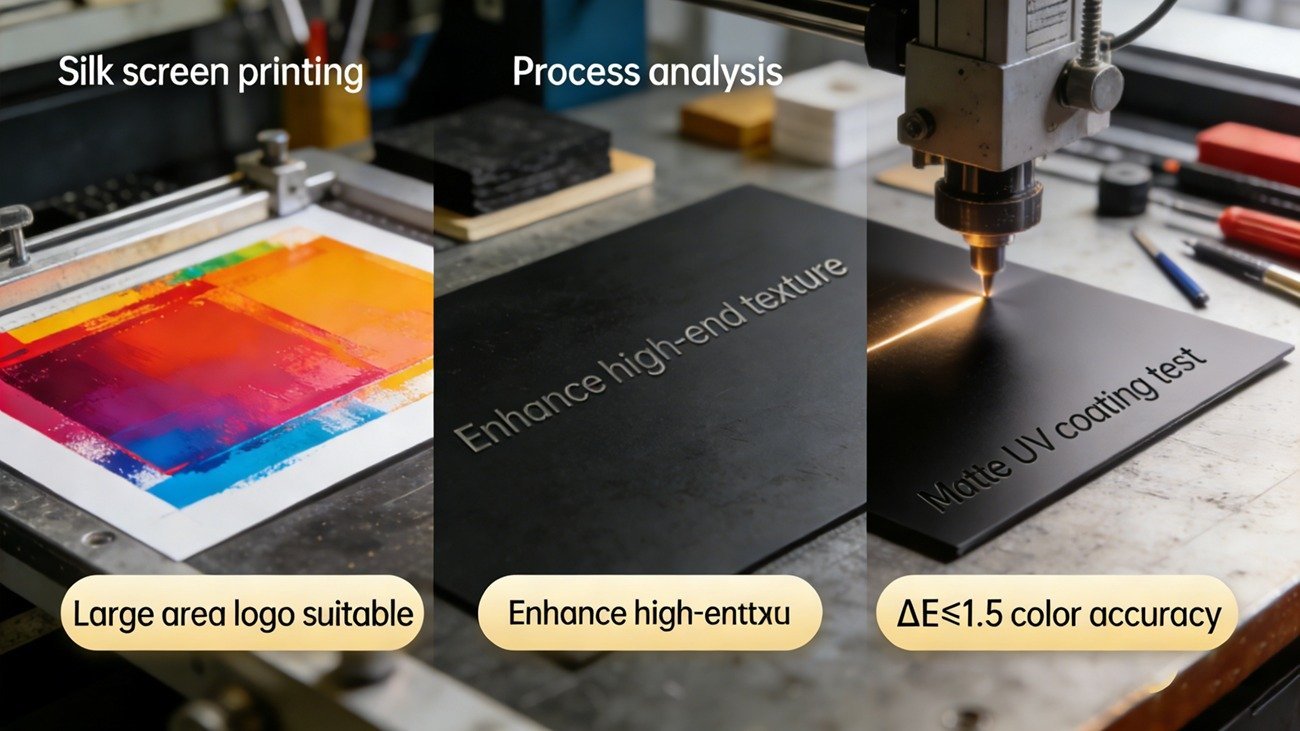

-Accurate printing and surface treatment: We are proficient in screen printing, hot stamping, matte UV coating, and embossing processes, each of which perfectly matches your design (for example, hot stamping process is suitable for high-end jewelry logos, and screen printing process is suitable for brightly colored cosmetic packaging).

-Strict quality control: Multi process inspection ensures material consistency and process accuracy - color difference Δ E ≤ 1.5 (ensuring brand color consistency), die-cutting accuracy reaches 0.1mm, and durability during transportation is ensured through structural testing.

-Sustainable innovation: We come standard with non-toxic and environmentally friendly water-based ink, optimize material usage, reduce waste - while ensuring packaging performance and aesthetics.

Design and Customization:

Efficient customization begins with selecting materials and processes that meet your goals. Our main options are categorized by application scenarios:

Material Application

-FSC certified paper: an ideal choice for environmentally friendly brands, 180-300gsm is suitable for cosmetic boxes, gift boxes, and food packaging - fully compliant with EU and US sustainability regulations, and can safely come into direct contact with food.

-Recycled corrugated cardboard: Three layer (lightweight protection) or five layer (heavy-duty seismic resistance) suitable for electronic toys, fragile electronic products, or large items -100% recyclable and does not affect transportation safety.

-Specialty paper: Matte or glossy coated paper, creating high-end aesthetics, scratch resistant surface treatment, very suitable for products that require frequent contact such as jewelry boxes or high-end gift sets.

Printing and post-processing technology

-Screen printing: suitable for eye-catching colors and large logos on cosmetics or gift boxes, with extremely high durability, suitable for long-term storage and shelf display.

-Hot stamping: Adding gold/silver foil decoration to luxury brands (jewelry, wine boxes) to enhance product texture without increasing packaging thickness or weight.

-UV coating: provides a scratch resistant and stain resistant surface for electronic product packaging, ensuring that brand logos and details are clearly visible during transportation and sale.

We provide practical advice for you

We provide business oriented practical advice to help you strike a balance between technical performance, budget constraints, and brand goals:

-Cost control: Select materials based on product weight (e.g. 180g/square meter for lightweight cosmetics and 300g/square meter for heavy jewelry) to avoid excessive design. We provide transparent prices for each process, with no hidden costs.

-Transportation adaptability: Choose corrugated cardboard for long-distance or international transportation, FSC certified paper for local retail - we will select suitable materials based on your distribution model to minimize damage and logistics costs.

-Compliance assurance: FSC certified materials and water-based inks comply with EU REACH regulations and US FDA standards - this is crucial for cross-border sales of food, cosmetics, and children's products, simplifying customs clearance processes.

Frequently Asked Questions:

What is the difference between FSC certified paper and recycled paper?

FSC certified paper ensures sustainable procurement (without involving deforestation), while recycled paper uses post consumer waste. We will assist you in making a choice based on your brand's environmental values and target market preferences.

Which printing technique is most suitable for printing small characters?

Digital printing is most suitable for text below 8pt (ensuring clarity), while screen printing excels at printing eye-catching patterns. We will evaluate your design details and recommend the best craftsmanship for you.

Can environmentally friendly materials withstand transportation tests?

Sure - our FSC certified paper paired with corrugated cardboard lining has a damage rate of less than 0.5% for cross-border transportation, balancing sustainability and safety.

How does material thickness affect cost?

Thicker paper (over 300 grams) will increase costs by 15-20%. We will recommend the optimal thickness based on the weight, purpose, and brand positioning of your product to avoid unnecessary expenses.

Do you provide material samples?

Yes, after order confirmation and before mass production, we provide samples for you to test the quality and appearance before mass production.

The packaging materials and processes do not need to be too complicated. With Crown Win Manufacturer's professional expertise, we will provide you with tailored recommendations that balance durability, aesthetics, sustainability, and cost. Contact our team for free material samples and customized quotes - let's work together to create precise and practical packaging that enhances your brand image.